mebs Hemera WaCo Mod

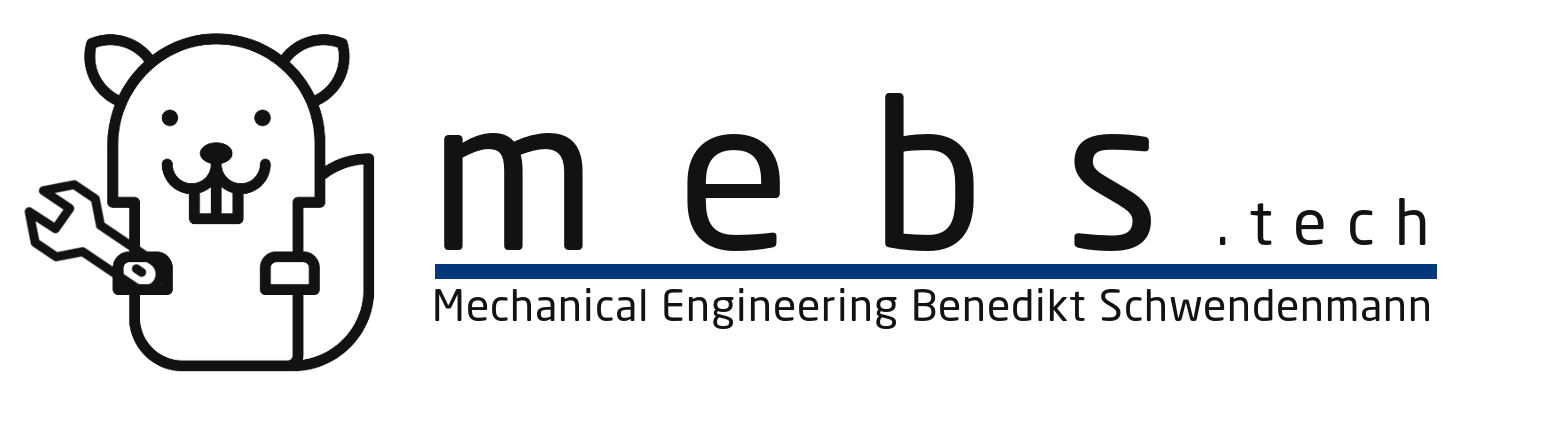

The mebs Hemera WaCo Mod expands the E3D Hemera with water cooling. The system enables the features of the compact designed extruder with all its benefits inside a heated chamber. It is designed for fast plug & play installation and is fully compatible with all E3D Hemera components.

Printing inside heated chambers

With the new mebs Hemera WaCo Mod, the E3d Hemera can now develop its full performance in heated chambers as well. Heat creep due to insufficient cooling is a thing of the past now. Another advantage of the system is that the motor is also cooled thanks to the enlarged contact surface.

Heated chambers enable greater strength and reduce the risk of warping when printing with technical polymers like Nylon, Polycarbonate and ABS.

Plug & Play

In a few simple steps the mebs Hemera WaCo Mod is installed on a E3D Hemera. After filling the cooling loop, the system can be used immediately. The screws and tools required for this are included in the box.

Compatibility

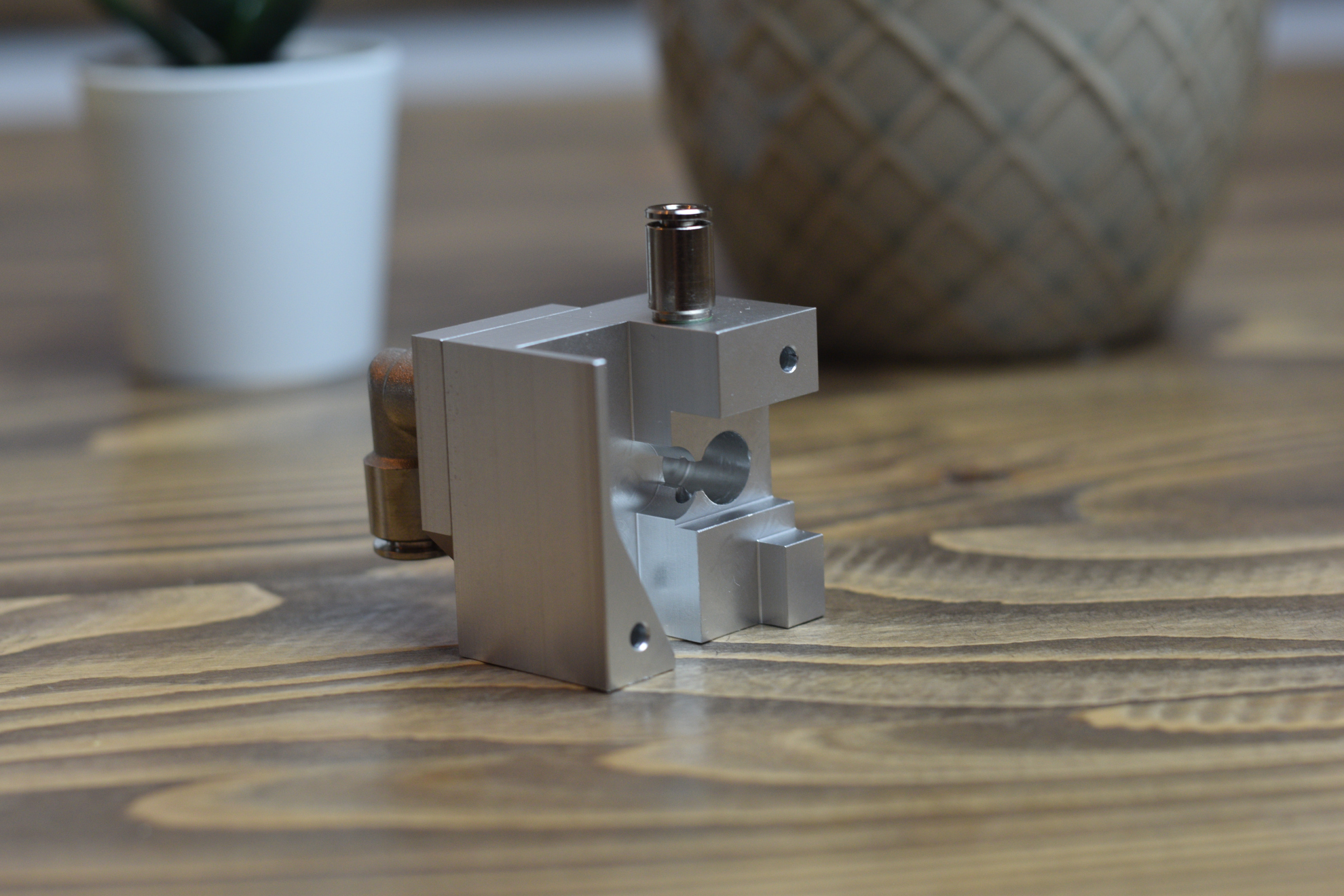

The mebs Hemera WaCo Mob is fully compatible with all E3D Hemera components. Both the heatbreak, the hotend and all the gears can be adopted.

The E3D Water Cooling Kit can be used, but the silicone tubes do not work with the Festo push fittings. It is recommended to replace them with PVC-tubes.

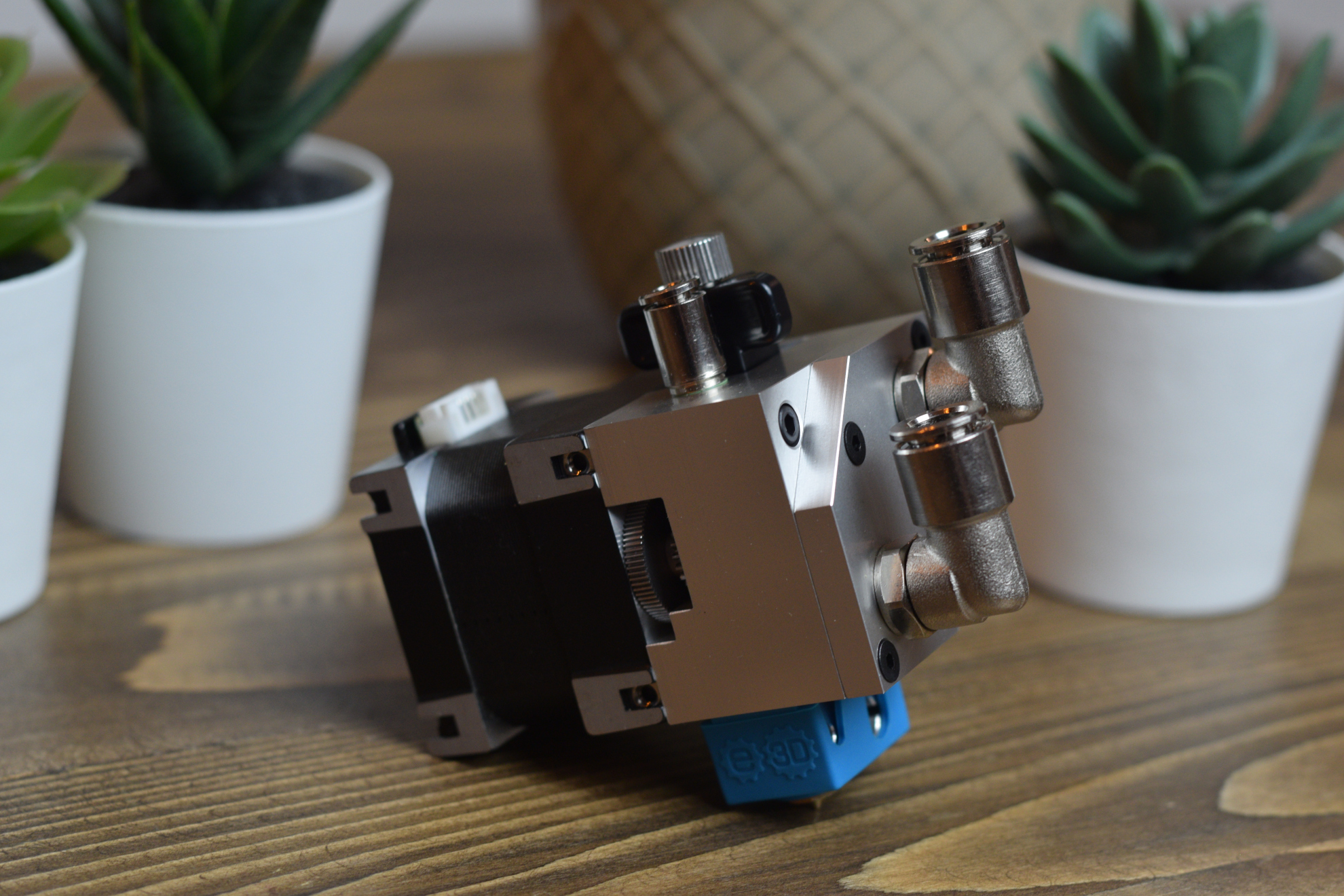

By default, 6 mm Festo push fittings are installed. Those can be swapped out to a smaller or lager tube diameter. Pay attention to the thread size G1 / 8 “.

Sustainability “Made in Germany”

The product is “Made in Germany” to enable short delivery routes and provide the highest quality. The packaging is made from sheet metal and can then be used as storage for tools or spare parts afterwards. The inlay and the bag for the tools are made of paper and can be recycled in an environmentally friendly way.

Where to buy

https://www.dold-mechatronik.de/mebs-Hemera-WaCo-Mod-EN

AdviceWhen using a copper radiator, the usage of cooling fluid is required. Otherwise, the parts can corrode.

The maximum chamber temperature is set by the components from E3d. The motor should not exceed a temperature of 85 °C.

The usage of PVC-tube is recommended.

Kit includes

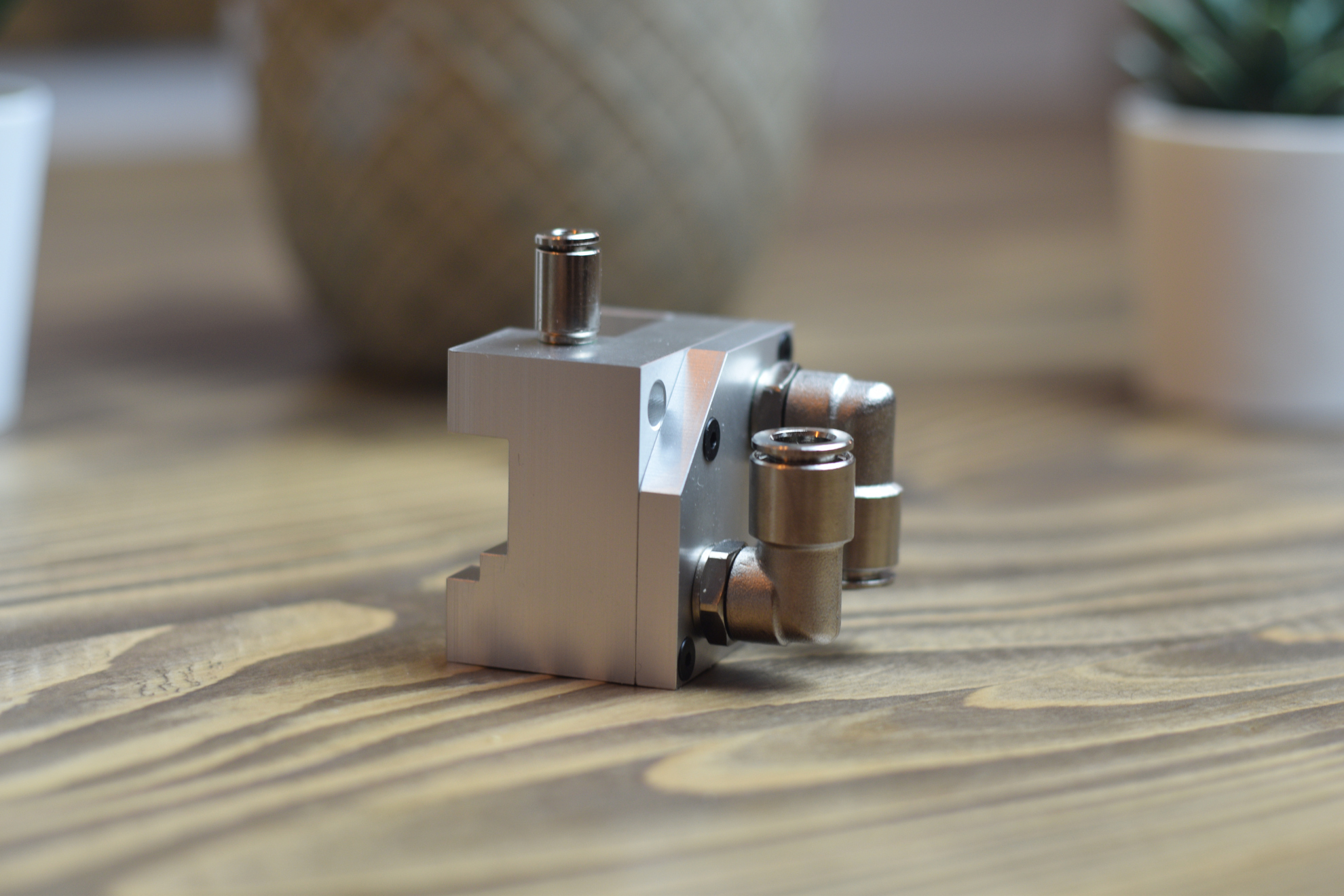

| Cooling body | Nature anodized aluminum |

|---|---|

| Top cap | Nature anodized aluminum |

| Sealing | 2 x O Ring NBR 70 35 x 1,5 |

| Screws | 2 x M3 x 30 socket head DIN 912 black 4 x M3 x 10 flat head ISO 10642 black |

| Push fittings | 2 x Festo NPQH-L-G18-Q6-P10 1 x Festo NPQH-DK-M5-Q4-P10 |

| Pin | DIN 7 A1 4 X 24 h8 |

| L-Keys | 1 x ISO 2936 steel Hex 2 tempered 1 x ISO 2936 steel Hex 2,5 tempered |

| Thermal paste | 0,5 g Termopasty Paste H |

Recommendations

PVC-Tube:

https://www.dold-mechatronik.de/PVC-Schlauch-SR1-PVC-6-4-TP-50-Laenge-1-Meter

Alphacool D5 pump (8 - 24 V):

https://www.alphacool.com/shop/pumpen/alphacool-pumpen/24122/alphacool-vpp655-single-edition?c=20558

Cooling fluid:

Reservoir:

Radiator:

Matching push fittings for Alphacool components: